INSECT PROTEINS FROM SUSTAINABLE PRODUCTION

Worldwide population and consequently need for food is rising continuously, eating habits are changing significantly. According to the world population growth, consumption of fish has considerably increased. While the annual global per capita consumption of fish still was 10 kg in 1960, it already amounted to 19 kg on average in 2012 according to the FAO.

Nearly half of fishery meanwhile is based on aqua culture or aqua farming – originally a solution approach to ensure feeding and above all to reduce overfishing of the world’s oceans. But in fact, things are quite different: Feeding fish in fish farms requires fishmeal and consequently there is an increase in production of fishmeal. In order to cover the demand, catch amount of some kinds of fish such as the Peruvian anchoveta are overfished already. Around 31.4 % of global fish stock is overfished and another 58.1 % is fully fished.* Many fish farms in addition cause environmental damage, e.g. due to the use of chemicals and antibiotics and many a valuable habitat is taken by the wide ranging breeding stations in a lot of regions. Thus fishmeal as protein source for animal feed not only is ecologically problematic it also becomes increasingly scarce and more expensive.

Along with scientific support, Maschinenfabrik Reinartz continually develops new, innovative options for animal feed production using pressing processes.

Production of concentrated feed from insect proteins can be an environmentally friendly alternative to conventional feed. Protein based on fly larvae is an ideal alternative to fish meal in the animal feed industry.

A high-protein feed flour is extracted from larvae of the black soldier fly (Hermetia illucens). In extensive tests insect flour turned out to be an excellent substitute for fishmeal. After processing of the dried fly larvae, the insect flour has a protein content of over 62 %.

Due to the short life cycles, the breeding period of insects is short and production requires relatively little space. The soldier fly feeds from food waste and organic waste as well as compost. This way, it contributes to solve and reduce the disposal problem of many farmers. Insect flour already has been certified as biological animal feed by the environmental organisation Naturland e.V..

Many reasons to use insect flour as protein source for animal feed. And the demand for proteins probably will increase by up to 50 % until 2050 – a gap which can be closed by means of insect flour easily and environmentally friendly.

Maschinenfabrik REINARTZ supports the innovative technology for the efficient production of insect meal by building special purpose presses and by planning the entire process – from the crude material to the finished product storage.

*Source: SOFIA report 2016 of the FAO

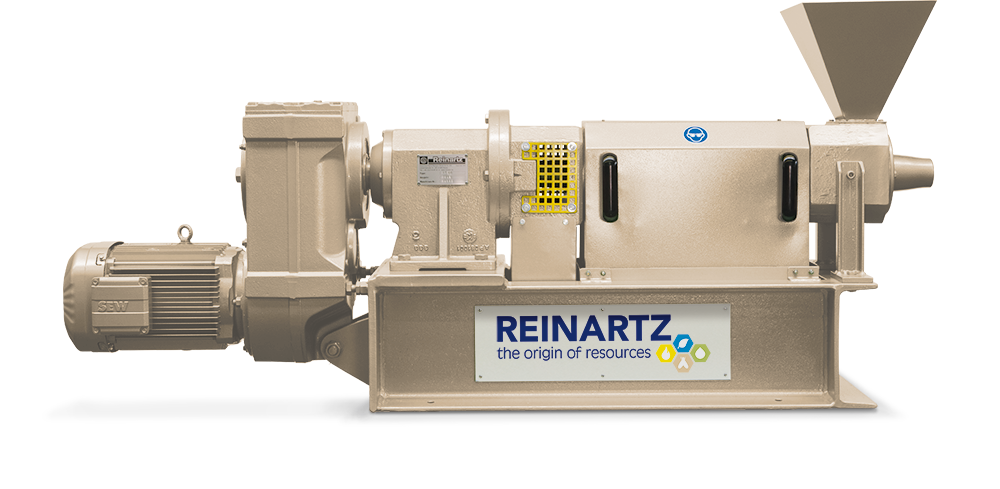

The Reinartz screw press type TP 04 is a ready-made press for mechanical degreasing of dried fly larvae. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame.

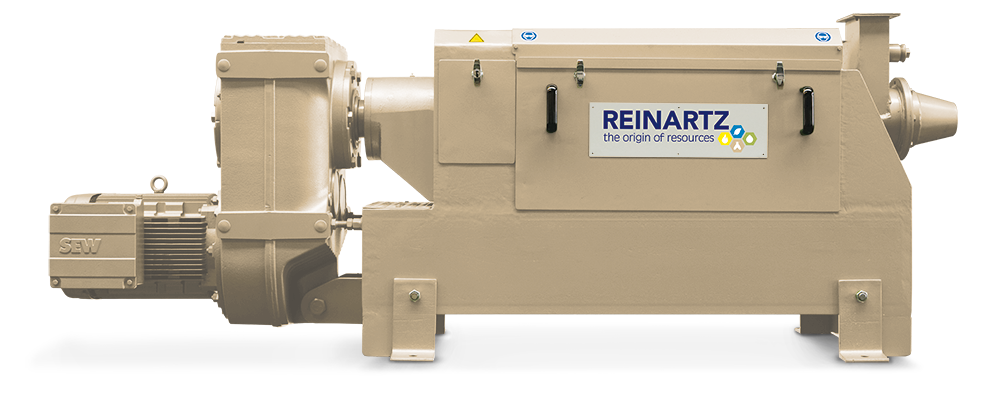

The Reinartz screw press type TP 04 is a ready-made press for mechanical degreasing of dried fly larvae. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame. The Reinartz screw press type TP 07 is a ready-made press for mechanical degreasing of dried fly larvae. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame.

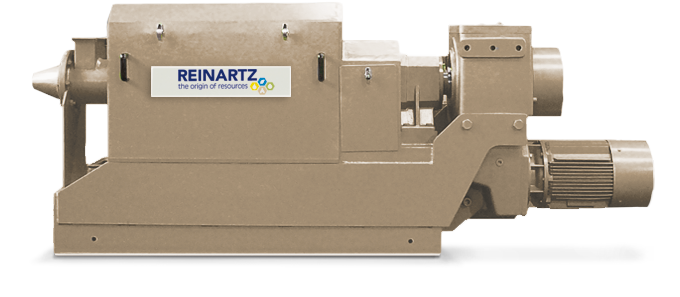

The Reinartz screw press type TP 07 is a ready-made press for mechanical degreasing of dried fly larvae. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame. The Reinartz screw press type TP 15 is a ready-made press for mechanical degreasing of dried fly larvae. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame.

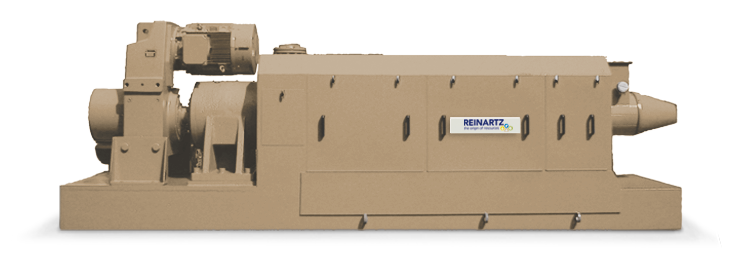

The Reinartz screw press type TP 15 is a ready-made press for mechanical degreasing of dried fly larvae. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame. The Reinartz screw press type TP 22 is a ready-made press for mechanical degreasing of dried fly larvae. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame.

The Reinartz screw press type TP 22 is a ready-made press for mechanical degreasing of dried fly larvae. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame. The Reinartz screw press type TP 30 is a ready-made press for mechanical degreasing of dried fly larvae. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame.

The Reinartz screw press type TP 30 is a ready-made press for mechanical degreasing of dried fly larvae. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame. The Reinartz screw press type TP 55 is a ready-made press for mechanical degreasing of dried fly larvae. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame.

The Reinartz screw press type TP 55 is a ready-made press for mechanical degreasing of dried fly larvae. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame. The Reinartz screw press type TP 90 is a ready-made press for mechanical degreasing of dried fly larvae. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame.

The Reinartz screw press type TP 90 is a ready-made press for mechanical degreasing of dried fly larvae. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame.