VEGETABLE OILS AND FATS IN PREMIUM QUALITY

Cold pressed is hot. That’s why, at Reinartz, we’ve been continually improving our cold press processes for more than 70 years. Reinartz’ screw presses guarantee gentle extraction of vegetable oils from various oil-bearing seeds and also the highest possible level of productivity.

The seeds are pressed in a unique process, without chemicals and with an extremely low level of frictional heat. Oil extracted in this way differs from refined oil extracted in a hot-press process in terms of its particularly high quality.

Vitamins and flavours are preserved and make the natural oil particularly valuable.

These high-quality oils are used in both the food industry and the cosmetic industry. They are also used in the bio-energy sector. All over the world, our customers rely on highly-efficient screw presses made by Maschinenfabrik Reinartz.

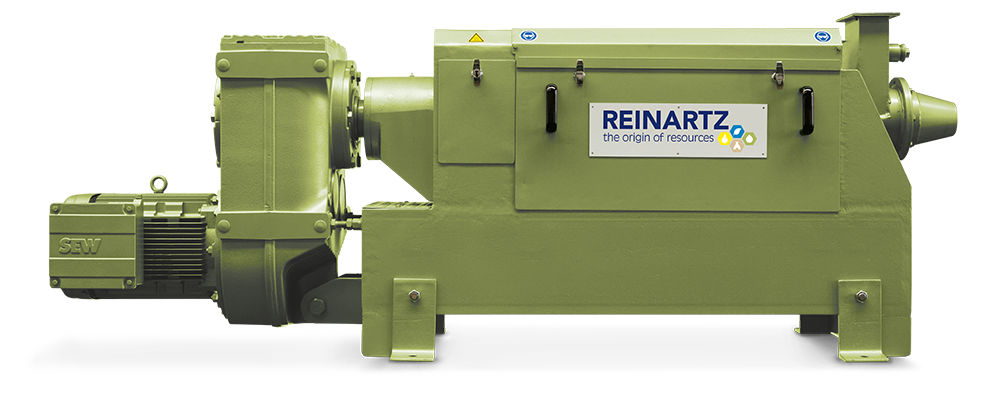

The Reinartz screw press type AP 10 is a ready-made press for cold-pressing oil seeds.

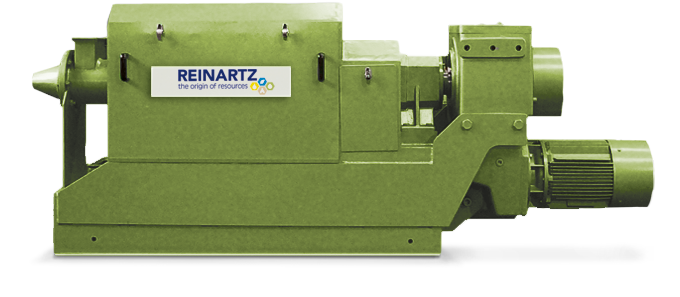

The Reinartz screw press type AP 10 is a ready-made press for cold-pressing oil seeds. The Reinartz screw press type AP 12 is a ready-made press for cold-pressing oil seeds.

The Reinartz screw press type AP 12 is a ready-made press for cold-pressing oil seeds.

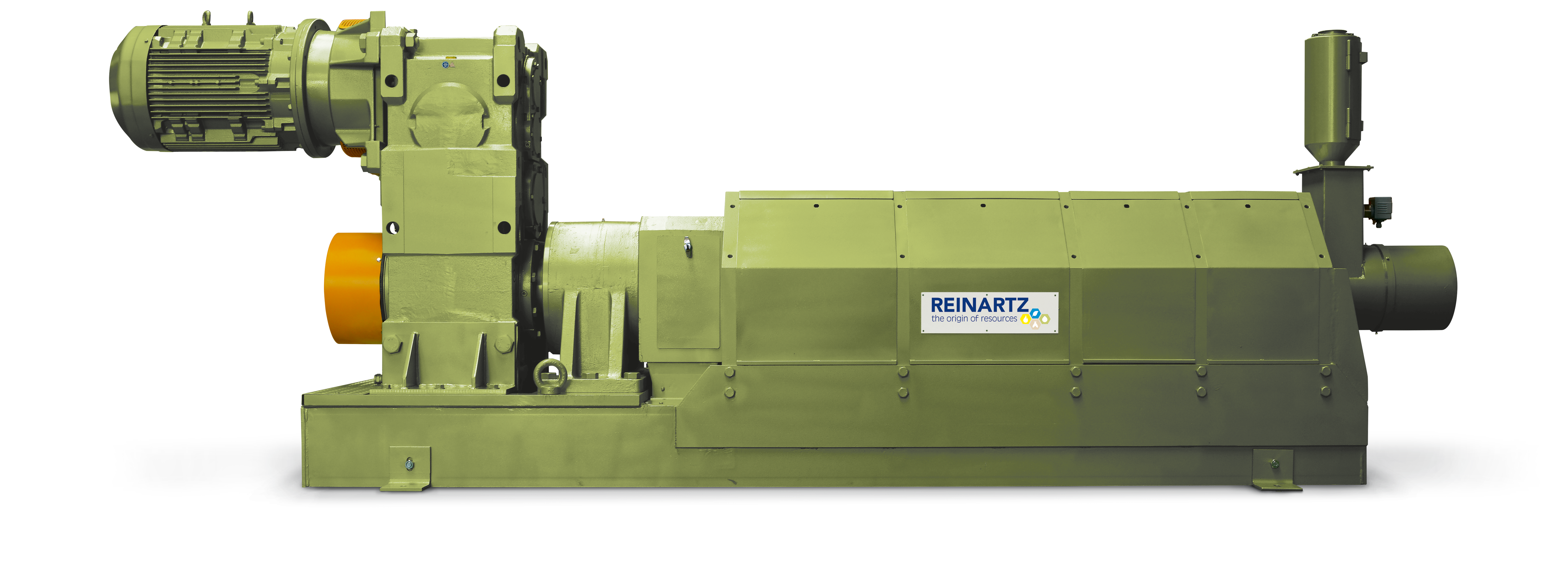

The Reinartz screw press type AP 14/30 is a ready-made press for cold-pressing oil seeds.

The Reinartz screw press type AP 14/30 is a ready-made press for cold-pressing oil seeds. The Reinartz screw press type AP 15 is a ready-made press for cold-pressing oil seeds.

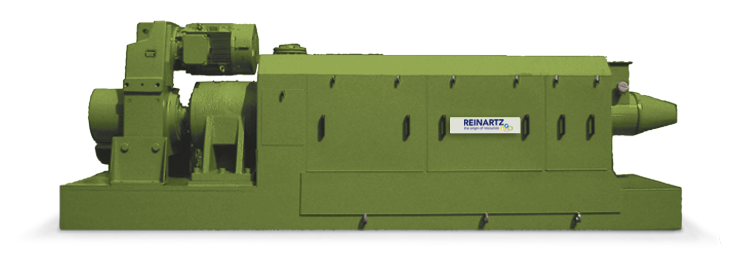

The Reinartz screw press type AP 15 is a ready-made press for cold-pressing oil seeds. The Reinartz screw press type AP 25 is a ready-made press for cold-pressing oil seeds.

The Reinartz screw press type AP 25 is a ready-made press for cold-pressing oil seeds.