The perfect animal feed

German chickens, pigs, cattle and other farm animals alone consume 224,000 tonnes of feed per day. That equates to around 8,900 lorry loads, according to the German Animal Nutrition Association’s calculations.*

Reinartz screw presses provide a highly-productive way of meeting this enormous demand for feed. Denn die Rückstände der Kaltpressverfahren werden in Reinartz Maschinen weiterverwertet, wieder gepresst und machen sich so in der Futtermittelindustrie nützlich. Press cake gained in Reinartz cold pressing process can be used directly or pressed a second time for producing high quality animal feed containing important vitamins and proteins.

Along with scientific support, Maschinenfabrik Reinartz continually develops new, innovative options for animal feed production oder mixtures using pressing processes. This includes the production of concentrated feed from insect proteins. Protein based on fly larvae is an ideal alternative to fish meal in the animal feed industry. This means they help reduce over-fishing of the world’s oceans and close the protein deficit in Europe.

Development of excellent, individual solutions for customers all over the world – that’s what Maschinenfabrik Reinartz stands for.

*see “Futtermittel für Nutztiere – Animal Feed for Livestock”

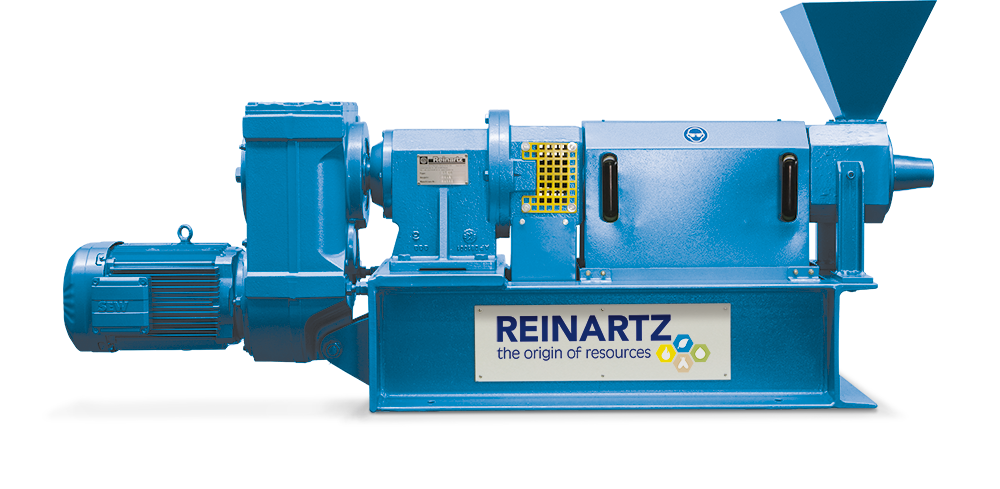

The Reinartz screw press type TP 04 is a ready-made press for mechanical removal of fat from dried, press-ready, semi-finished products. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame.

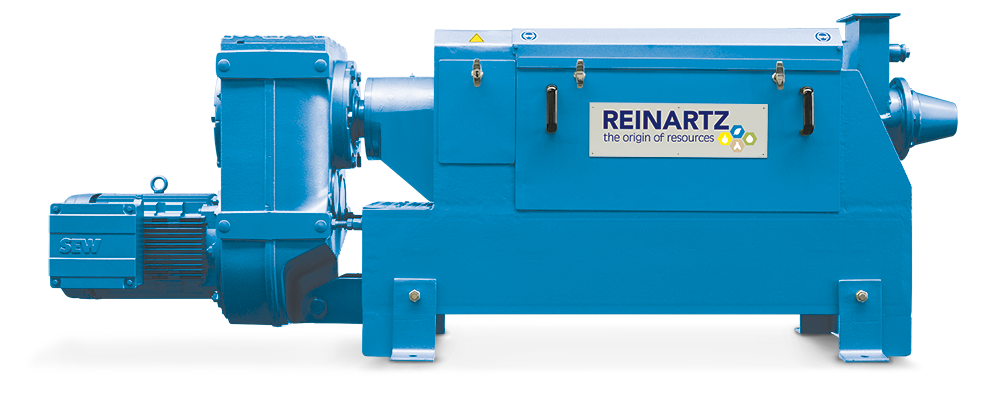

The Reinartz screw press type TP 04 is a ready-made press for mechanical removal of fat from dried, press-ready, semi-finished products. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame. The Reinartz screw press type TP 07 is a ready-made press for mechanical removal of fat from dried, press-ready, semi-finished products. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame.

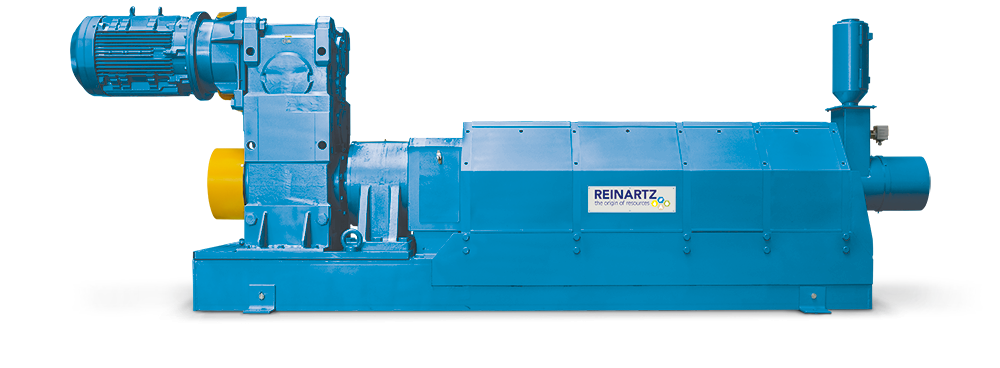

The Reinartz screw press type TP 07 is a ready-made press for mechanical removal of fat from dried, press-ready, semi-finished products. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame. The Reinartz screw press type TP 15 is a ready-made press for mechanical removal of fat from dried, press-ready, semi-finished products. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame.

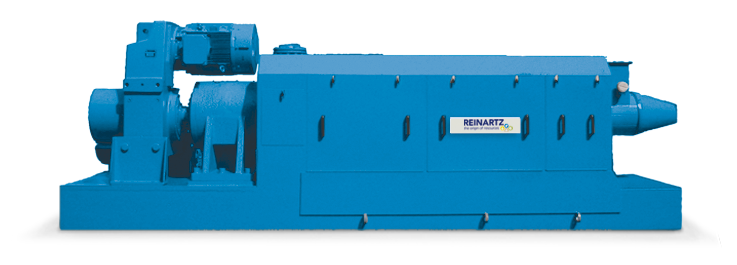

The Reinartz screw press type TP 15 is a ready-made press for mechanical removal of fat from dried, press-ready, semi-finished products. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame. The Reinartz screw press type TP 22 is a ready-made press for mechanical removal of fat from dried, press-ready, semi-finished products. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame.

The Reinartz screw press type TP 22 is a ready-made press for mechanical removal of fat from dried, press-ready, semi-finished products. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame. The Reinartz screw press type TP 30 is a ready-made press for mechanical removal of fat from dried, press-ready, semi-finished products. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame.

The Reinartz screw press type TP 30 is a ready-made press for mechanical removal of fat from dried, press-ready, semi-finished products. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame. The Reinartz screw press type TP 55 is a ready-made press for mechanical removal of fat from dried, press-ready, semi-finished products. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame.

The Reinartz screw press type TP 55 is a ready-made press for mechanical removal of fat from dried, press-ready, semi-finished products. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame. The Reinartz screw press type TP 90 is a ready-made press for mechanical removal of fat from dried, press-ready, semi-finished products. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame.

The Reinartz screw press type TP 90 is a ready-made press for mechanical removal of fat from dried, press-ready, semi-finished products. The fat expelled in the press is collected in a collection tank integrated into the base of the press frame.